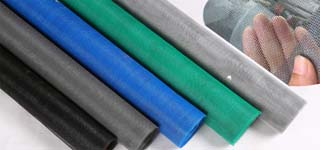

polyester fiberglass

___

Gel Coat Application Guide: Gel coat is the most common surface coating used in the fabrication and repair of fiberglass reinforced products. Gel Coat is a specially formulated two-part polyester resin that is designed to be the first layer of resin applied in a mold when making a polyester or vinyl ester composite part.

Evercoat Polyester Fiberglass Repair Kit: Product Overview Best for repair of fiberglass and metal surfaces Will rebuild rotted-out areas on fenders, body sections and rocker panels Also used for forming special customized shapes Contains: 8 fl. oz. resin, 1/4 oz. liquid hardener, 3 sq. ft. fiberglass cloth, mixing stick, plastic spreader.

TotalBoat Polyester Finishing Resin: Two-part polyester resin for use as a final or finish coat over laminating resin. It contains wax, and cures tack-free to form a hard, clear finish on fiberglass, metal, and wood. Sand, paint, or apply gelcoat upon full cure. Wet sand and buff for a glossy appearance.

Polyester resin is brittle and prone to micro-cracking. The shelf life of polyester resin is about 6 months – 1 year. You can vary the cure time of polyester resin by adding more or less of MEKP catalyst. Polyester resin generally costs slightly less than epoxy resin. Polyester off-gases VOCs and has strong, flammable fumes. Polyester Resin Vs. Epoxy Resin.

Product Title Bondo Fiberglass Resin Repair Kit, 00420, 0.45 Pint Average rating: 4.2 out of 5 stars, based on 31 reviews 31 ratings Current Price $17.88 $ 17 . 88. Fiberglass Resins.

How to Seal Wood With Polyester Resin: Polyester resin is used for laminating fiberglass reinforcement, molds and, yes, waterproofing wood. It comes in two types, finishing and laminating. Finishing resin is basically laminating resin with added wax that allows it to fully harden.

. Fiberglass / Resins.

Fiberglass (American English), or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber.The fibers may be randomly arranged, flattened into a sheet (called a chopped strand mat), or woven into a fabric.The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinylester—or a. Fiberglass.

Polyester Resin Vs. Epoxy Resin: Compatible with only fiberglass materials, polyester resins have limited use for laminating, seaming and repairing. Both the epoxy and polyester resins are popular in the marine industry, but epoxy strength and durability make it the first choice. Epoxy resins reinforce such materials as glass, carbon and aerospace materials.

Polyester Resins for Composites: Polyester Resins are the most widely used resins in the composites industry. Sometimes referred to as Fiberglass Resins, Polyester Resins are less expensive, offer some corrosion resistance, and are more forgiving than epoxies.

6 Steps to Proper Surface Prep for Gelcoat – Fiberglass: Applying gelcoat is a process that requires a bit of skill, a lot of know-how and the right tools and materials. So, before you spray or brush the gelcoat on, you want to make sure you prepare the surface you are recoating for the best results. Step #1 – You will want to start off….